WADA - Laminated Veneer Lumber-Door Jamb Cn

Laminated Veneer Lumber-Door Jamb Cn

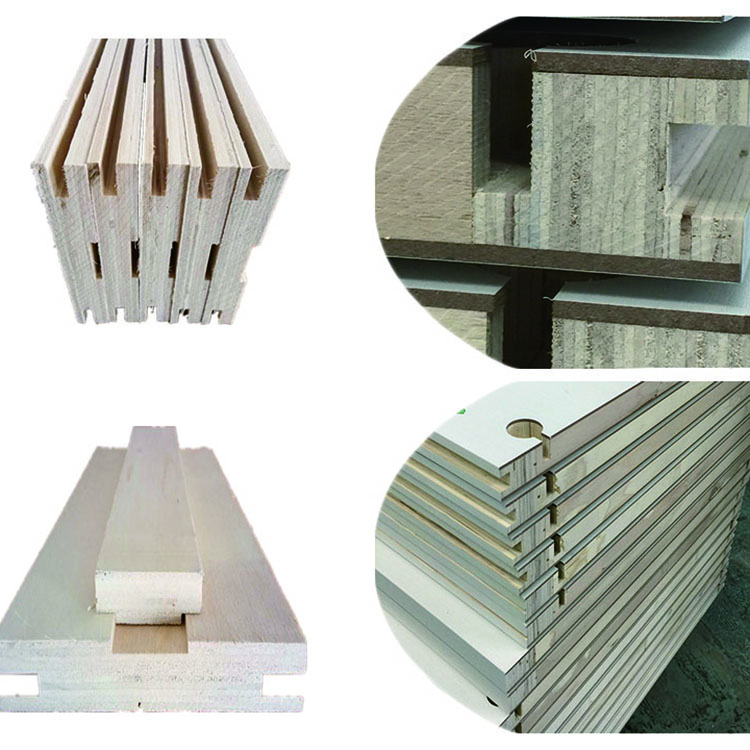

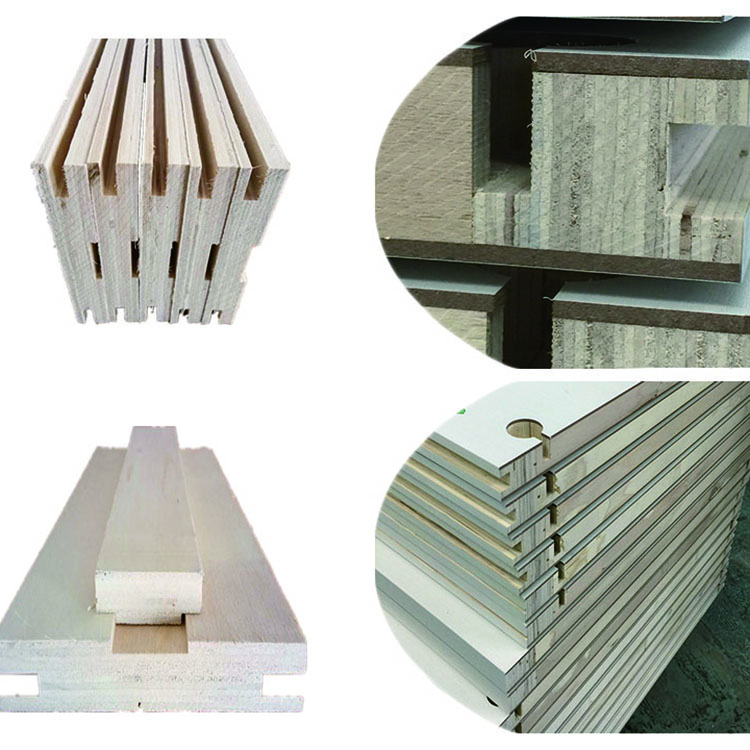

WADA offers a broad product range of Laminated veneer lumber (LVL) for door components, door jamb, door frame, stile and rail doors, and window components.

Product Specifications

| Wood species | Poplar, Eucalyptus, Eucalyptus&Poplar, Paulownia&Poplar, etc. |

| LVL Sizes | Thickness: 9-60mm; Width:10mm-1220mm; Length:100mm-5000mm |

| Minimum Tolerance | Thickness ±0.2mm; Width ±0.2mm; Length -0, +1mm |

| Glue | Urea-formaldehyde glue, Phenolic glue etc. |

| Moisture content | 8%-12% |

| Warping Rate | below 2‰ |

| Bending rate | below 1.5‰ |

| Density | 530-650kg/m³ |

| Emission formaldehyde standard | CARB P2, F☆☆☆☆, E0, E1, E2 |

| Certification | CARB/FSC/EU/JAS/F4S etc. |

| LVL Application | LVL door core, door components, window components, Door Jamb, Door frame, LVL framing, furniture frame, etc. |

| Packing | Standard export packing |

| MOQ | 3m³ |

| Supply ability | 5000m³/month |

| Payment | T/T, L/C, D/A, D/P etc. |

| Place of origin | JIANGSU/SHANDONG |

| Port of loading | LIANYUNGANG/QINGDAO |

| Final User | DAIWA HOUSE, SEKISUI HOUSE, etc. |

| Export experience | 7 years |

product advantage

laminated veneer lumber(LVL)can replace the solid wood, as an excellent material to make door core and door frames.

1. Multiple certifications: FSC, JAS, JIS and MLIT Minister certificate

2. High environmental protection rating: The products’ formaldehyde emissions are extremely low because of the use of Japanese F☆☆☆☆ standard glue together with a formaldehyde scavenger.

3. Low warping ratio: Reasonable drying process, Sufficient drying time, to make the moisture content be strictly controlled between 8%-12%, to ensure that the warping ratio of the LVL is below 2‰.

4. Special Treatment: Anti-mildew treatment, anti-insect (termites, insects, etc.) treatment

5. Custom processing: Planning, sanding, polishing, grooving, drilling, etc.

Post buying request

Contact us

- Penny

- +86-0411-83773730

- wada@wadatrade.com