Blog

Do you know how to identify the Furniture Grade Plywood?

Although you hear the term “furniture grade plywood” bandied around from time to time (usually by people who don’t know any better), there really is no such thing. Furniture is an application in which plywood is used; but there is no such grade of plywood. Rather, the term “furniture grade” is a loosely used term, primarily referring to plywood with a letter grade identifying the quality of face veneer, which would make it acceptable for use in building furniture.

This grade of finish is normally only found on hardwood plywood, sometimes referred to as “cabinet grade” plywood, because it is commonly used for making cabinetry. But it can also be found on softwood plywood, if you look hard enough. It’s impossible to find such a high quality finish on products like OSB (oriented strand-board) and MDF (medium-density fiberboard) because of the way they are made and the material they are made from.

Most hardwood plywood used to manufacture furniture and cabinetry, such as cabinets, tables, chairs, etc., comes graded as “A1,” referring to the face side being A-grade and the back side being grade 1. The grading system looks like this:

Visible Face Grades:

AA – Good or good sequence

A – Good

B – Good, sliced B, RC sound

C – Rotary cut solid

Back Face Grades:

Sound, same species, specifically cut

Solid, same species, specifically cut

Rotary Grain

Reject Back

The idea of calling some plywood “furniture grade plywood” comes from the use of high-grade hardwood plywood for making furniture, even though it is an inaccurate term. Cabinet grade plywood, on the other hand, is a term used most commonly for birch plywood, popular hardwood plywood for building kitchen and bathroom cabinets.

Doing this usually requires some careful machining and finish sanding, so as to match the pieces up in a way that makes them look like they belong, rather than you are trying to hide something.

It is best to cut the hardwood edge and corner pieces slightly proud, allowing you to plane or sand them flush with the plywood. You can’t take off from the plywood, if it is proud, as the face veneer is too thin to allow that, without damage. But the solid hardwood edge shouldn’t have any problems being trimmed and sanded.

Care must be taken, when cutting hardwood plywood, so as to not chip out the face veneer. Always cut from the back side of the sheet, to help prevent this. Taping the cut line, on both sides, with masking tape, will also help to prevent chipping and splintering.

PVC and plywood

Another style which is becoming more popular for classrooms, children’s beds and play rooms, and for patio furniture is to combine furniture grade plywood with furniture grade PVC. Since PVC pipe was invented, it seems that people have been on a continuing quest to find new ways of using it. A wide range of projects have been completed, including greenhouses, bike racks, soccer goalposts and furniture. The ease of working with PVC, coupled with the wide variety of connectors available, make it a prime building material for quick and easy projects.

Furniture grade PVC pipe is typically Schedule 40, just like the pipe used for plumbing; but it is available in a wide range of colors. The couplings however, are not rated and are usually a little thinner walled than those used for plumbing. That’s okay, as they are not put under the same stresses. The fittings do not have all the mold marks and markings on them, that you would find on fittings intended for plumbing use.

Combining cabinet grade plywood with the PVC provides much more strength than the PVC can provide alone. The weight of whatever is going to be on that piece of furniture can be held by the plywood, spreading that weight out, so that it doesn’t break the PVC framework. Attaching the plywood to the PVC pipe is done with hardware, just as with the industrial style furniture mentioned above.

Cabinet making

When making cabinets, hardwood plywood is used in a slightly different way, than when making furniture. Rather than trying to hide all the edges, the cabinet face pieces are often cut out of ¾” hardwood plywood and then assembled, as if the plywood was solid hardwood. Although the edges are left exposed, the only place where they will be visible is on the inside of the door opening, someplace that people don’t bother to look.

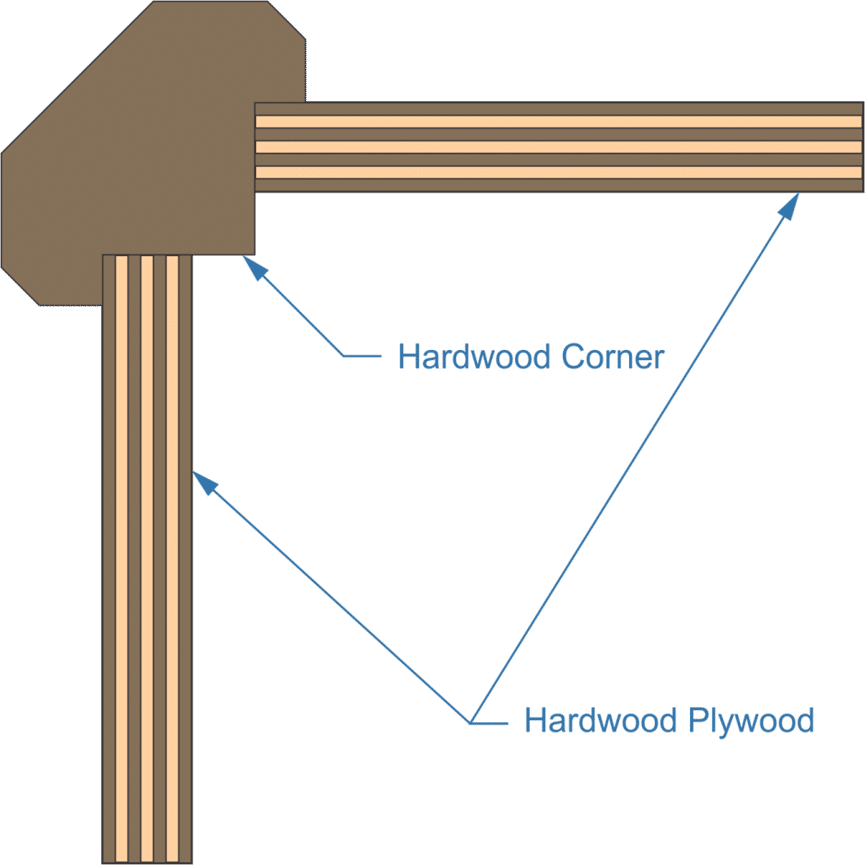

Generally speaking, when the front outside edges of the cabinets will be visible, such as the upper cabinets next to the sink, will have a trim piece attached at the corner, covering up the edge of the plywood. In all other cases, the edge of the plywood won’t be visible, once installed, because the cabinets will be butted up against one another or against appliances.

Hello. impressive job. I did not imagine this. This is a excellent story. Thanks!