Blog

How to install wood plastic composite wallboard

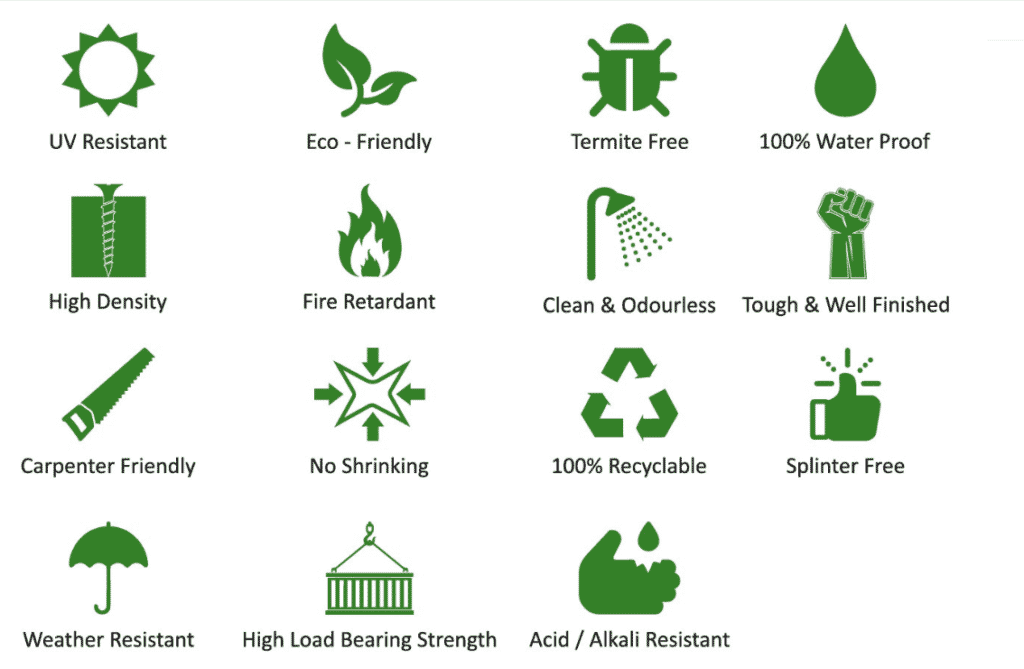

Wood-plastic exterior wall board makes the building appear simple and natural and beautiful, can resist all kinds of bad weather, and anti-corrosion and flame-retardant, easy to install. No matter in the production process or in the engineering practice, it can not pollute the environment and can be reused, so it is an ideal decorative material for environmental protection.

The plastic-wood composite Siding is light in weight, insulated, moisture-proof, flame-retardant, acid-alkali resistant, corrosion-resistant; stable, good dielectric, durable, anti-aging, easy to weld and bond; strong flexural strength and impact toughness, high elongation when rupture; smooth surface, Bright color, very decorative, wide application of decoration, simple construction technology, easy installation.

From the professional consideration of installation, WPC wall cladding is suggested to be installed by professional construction personnel. Please clean the wall before installation and make the wall dry, smooth, and clean. If there are construction industry regulations or local regulations, please install them according to the regulations.

- fixation of the keel (as shown in the figure)

Steel keel is also usually used. The space between keels should be less than 400 mm. The steel keel should be fixed on the wall with an expansion screw. Antirust paint should be applied to the steel keel.

Or use our WPC keel, Install the plastic wood keel evenly and fix it on the flat wall with expansion Screws. It is recommended that the distance between each keel be less than 400mm. It needs to keep 3-5mm at the joint of the keel to keel to prevent expansion. When installing the WPC keel, In the position of the expansion tube, drill the hole on the keel First, Then put the plastic expansion tube into the hole, Screw the screws into the expansion tube, and fix the keel to the wall. the nail head should be all screwed into the keel, not exposed outside the keel, otherwise, it may lead to an uneven board surface.

2. Fixation of wood-plastic wallboards:

As shown in the figure below, take HM 156X21mm as an example

When installing the WPC wall panel, the stainless steel starting fastener should be used first to fix the first piece of board.

Step 1: First use a smaller diameter drill, lead a hole on the Part where the SS Screws into the wallboard, then screw the first row of the wallboard into the keel.

Step 2: push the cut WPC wallboard to the appropriate position, then screw the wallboard, and so on, install in turn. It is recommended that the length of each WPC wallboard should not exceed 2.9 meters.

Step 3: After installation to the Wall, each row of the last piece of the WPC wall panel uses stainless steel tapping screws directly fixed on the keel.

Step4:Install “L” shape Side cover. It can be fixed with stainless steel screws.

For plastic wood materials, the water absorption is about 0.2% and the expansion rate is about 0.5%, so when installing this wall Cladding, please leave the corresponding gap between each board (3-5 mm). An electric drill is a tool that must be used in the installation process; because the plastic wood material has a certain brittleness, when fixing the keel with the WPC material, the lead hole is first drilled, then Fix screws, but don’t directly nailed. Otherwise, the material may crack and break. A nail gun can be used to fix the wall cladding too. Labor gloves are best used during construction. It is recommended to use stainless steel screws to fix the screws during installation.

Good day! This is my 1st comment here so I just wanted to give a quick shout out and tell you I truly enjoy reading through your articles. Can you recommend any other blogs/websites/forums that cover the same subjects? Appreciate it!

Hi there to all, it’s truly a pleasant for me to pay a visit this site, it includes important Information.

Hey very nice blog!

Marvelous, what a website it is! This web site presents helpful data to us, keep it up.

Awesome blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple tweeks would really make my blog jump out. Please let me know where you got your design. Thank you

I’ve been browsing on-line more than 3 hours lately, yet I by no means found any interesting article like yours. It’s pretty price sufficient for me. In my view, if all site owners and bloggers made excellent content material as you did, the web can be much more helpful than ever before.

This design is steller! You definitely know how to keep a reader amused. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Great job. I really loved what you had to say, and more than that, how you presented it. Too cool!

Wow, amazing blog layout! How lengthy have you ever been running a blog for? you make running a blog look easy. The full glance of your website is excellent, as smartly as the content material!

Excellent way of telling, and fastidious article to get information regarding my presentation subject, which i am going to present in college.

Hello i am kavin, its my first time to commenting anywhere, when i read this article i thought i could also create comment due to this brilliant article.

Thank you for every other great article. The place else could anybody get that kind of info in such an ideal means of writing? I’ve a presentation next week, and I’m on the look for such info.

Hi there, just wanted to tell you, I loved this post. It was practical. Keep on posting!

Have you ever thought about including a little bit more than just your articles? I mean, what you say is important and all. However just imagine if you added some great images or videos to give your posts more, “pop”! Your content is excellent but with pics and videos, this site could definitely be one of the greatest in its field. Excellent blog!

I do trust all the concepts you’ve offered in your post. They are very convincing and can definitely work. Still, the posts are too short for starters. Could you please extend them a bit from subsequent time? Thanks for the post.

Way cool! Some very valid points! I appreciate you penning this post and the rest of the website is also really good.

Good blog post. I absolutely love this site. Continue the good work!

You should take part in a contest for one of the most useful sites on the net. I’m going to highly recommend this site!

Nice weblog right here! Additionally your site loads up fast! What host are you the usage of? Can I am getting your affiliate hyperlink to your host? I want my web site loaded up as quickly as yours lol

Everything is very open with a very clear description of the challenges. It was really informative. Your website is very helpful. Thanks for sharing!

Saved as a favorite, I like your website!

Hi there, just wanted to tell you, I loved this blog post. It was inspiring. Keep on posting!

What’s Happening i am new to this, I stumbled upon this I’ve discovered It absolutely helpful and it has helped me out loads. I’m hoping to give a contribution & assist different customers like its helped me. Good job.

Way cool! Some extremely valid points! I appreciate you penning this article plus the rest of the site is also really good.

WOW just what I was looking for. Came here by searching for %meta_keyword%

Nice post. I learn something new and challenging on blogs I stumbleupon everyday. It will always be interesting to read through articles from other writers and practice a little something from other sites.

If some one wants expert view concerning running a blog after that i recommend him/her to pay a quick visit this webpage, Keep up the nice job.

I am really glad to glance at this blog posts which includes tons of helpful information, thanks for providing these kinds of information.

Hey there! This is my first visit to your blog! We are a team of volunteers and starting a new initiative in a community in the same niche. Your blog provided us valuable information to work on. You have done a outstanding job!

Thanks, I’ve been looking for this for a long time

Every weekend i used to go to see this web page, because i want enjoyment, for the reason that this this web page conations in fact fastidious funny material too.

fantastic put up, very informative. I ponder why the opposite specialists of this sector don’t understand this. You must continue your writing. I am sure, you’ve a great readers’ base already!

You should take part in a contest for one of the highest quality blogs online. I am going to recommend this site!

I really like your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you? Plz answer back as I’m looking to design my own blog and would like to find out where u got this from. thanks a lot

Exceptional post but I was wanting to know if you could write a litte more on this subject? I’d be very thankful if you could elaborate a little bit more. Thanks!

Hello there! This post couldn’t be written any better! Reading this post reminds me of my good old room mate! He always kept talking about this. I will forward this post to him. Pretty sure he will have a good read. Thanks for sharing!

Hurrah, that’s what I was exploring for, what a information! existing here at this webpage, thanks admin of this website.

Hi to all, how is all, I think every one is getting more from this site, and your views are good in favor of new visitors.

Hi there every one, here every one is sharing these experience, therefore it’s pleasant to read this web site, and I used to go to see this weblog daily.

Hi, I do believe this is a great website. I stumbledupon it 😉 I am going to return once again since i have book marked it. Money and freedom is the greatest way to change, may you be rich and continue to guide other people.

Remarkable! Its truly awesome piece of writing, I have got much clear idea on the topic of from this paragraph.

I’ve been surfing online more than 4 hours today, yet I never found any interesting article like yours. It is pretty worth enough for me. In my opinion, if all webmasters and bloggers made good content as you did, the web will be a lot more useful than ever before.

For newest news you have to pay a visit web and on web I found this web page as a finest web site for most recent updates.

Nice post. I learn something new and challenging on sites I stumbleupon on a daily basis. It will always be exciting to read through content from other authors and use a little something from other sites.

I’m amazed, I must say. Rarely do I encounter a blog that’s both equally educative and amusing, and let me tell you, you have hit the nail on the head. The issue is something which too few men and women are speaking intelligently about. I am very happy that I stumbled across this during my search for something regarding this.

Hello all, here every one is sharing such knowledge, therefore it’s nice to read this website, and I used to pay a visit this blog daily.

I have to thank you for the efforts you have put in writing this website. I am hoping to see the same high-grade content from you in the future as well. In fact, your creative writing abilities has inspired me to get my own website now 😉

I was able to find good advice from your blog posts.

Hey there, You’ve done an excellent job. I will definitely digg it and personally suggest to my friends. I am confident they’ll be benefited from this site.

Great blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple adjustements would really make my blog stand out. Please let me know where you got your theme. Thanks

I like it when folks get together and share ideas. Great blog, keep it up!

I enjoy what you guys are up too. This sort of clever work and exposure! Keep up the great works guys I’ve added you guys to my personal blogroll.

I got this site from my friend who told me on the topic of this site and at the moment this time I am visiting this web page and reading very informative articles here.

whoah this weblog is great i love reading your articles. Keep up the great work! You realize, a lot of persons are hunting around for this info, you can help them greatly.

you are truly a excellent webmaster. The site loading speed is amazing. It seems that you’re doing any unique trick. Also, The contents are masterpiece. you’ve performed a fantastic job on this matter!

I savour, cause I found exactly what I was looking for. You’ve ended my four day long hunt! God Bless you man. Have a nice day. Bye

Thanks for the marvelous posting! I definitely enjoyed reading it, you could be a great author. I will ensure that I bookmark your blog and will often come back from now on. I want to encourage you to continue your great job, have a nice day!

Great work! That is the kind of information that are supposed to be shared around the internet. Shame on Google for now not positioning this publish upper! Come on over and visit my website . Thanks =)

I like the helpful info you provide in your articles. I’ll bookmark your weblog and check again here frequently. I am quite sure I’ll learn many new stuff right here! Good luck for the next!

Having read this I believed it was very enlightening. I appreciate you taking the time and energy to put this article together. I once again find myself personally spending a lot of time both reading and posting comments. But so what, it was still worthwhile!

I am no longer certain the place you’re getting your info, however great topic. I needs to spend some time studying much more or working out more. Thank you for great info I was in search of this information for my mission.

Very nice article, totally what I was looking for.

fantastic put up, very informative. I wonder why the other experts of this sector don’t understand this. You must proceed your writing. I am confident, you have a huge readers’ base already!

Every weekend i used to pay a visit this web site, as i want enjoyment, since this this website conations actually good funny information too.

Hello, I enjoy reading through your article post. I like to write a little comment to support you.

We are a bunch of volunteers and opening a brand new scheme in our community. Your site provided us with helpful information to work on. You have done an impressive task and our whole group can be thankful to you.

Your mode of telling all in this piece of writing is really fastidious, all be able to simply know it, Thanks a lot.

Wow, that’s what I was looking for, what a stuff! existing here at this weblog, thanks admin of this site.

Your means of telling all in this paragraph is genuinely fastidious, all be capable of effortlessly understand it, Thanks a lot.

My family members all the time say that I am wasting my time here at web, however I know I am getting experience every day by reading thes good articles or reviews.

What’s up friends, pleasant post and nice urging commented here, I am in fact enjoying by these.

What’s up, after reading this awesome post i am as well glad to share my experience here with friends.

Hi, just wanted to mention, I loved this blog post. It was helpful. Keep on posting!

Hi, yup this paragraph is in fact pleasant and I have learned lot of things from it about blogging. thanks.

Very soon this website will be famous amid all blog people, due to it’s pleasant articles

It’s nearly impossible to find knowledgeable people on this subject, but you sound like you know what you’re talking about! Thanks

This design is wicked! You definitely know how to keep a reader entertained. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Wonderful job. I really loved what you had to say, and more than that, how you presented it. Too cool!

Hi there colleagues, how is the whole thing, and what you desire to say about this post, in my view its truly remarkable in favor of me.

Nice weblog here! Additionally your site lots up very fast! What web host are you the usage of? Can I get your affiliate link for your host? I wish my web site loaded up as quickly as yours lol

Wonderful goods from you, man. I’ve bear in mind your stuff prior to and you are just too fantastic. I really like what you have received here, certainly like what you’re saying and the way in which by which you say it. You are making it enjoyable and you continue to care for to stay it wise. I can not wait to learn far more from you. This is really a great site.

Amazing blog! Do you have any tips for aspiring writers? I’m hoping to start my own blog soon but I’m a little lost on everything. Would you propose starting with a free platform like WordPress or go for a paid option? There are so many choices out there that I’m completely confused .. Any suggestions? Kudos!

hello there and thank you for your info – I have certainly picked up anything new from right here. I did however expertise several technical points using this site, as I experienced to reload the site many times previous to I could get it to load correctly. I had been wondering if your hosting is OK? Not that I’m complaining, but slow loading instances times will very frequently affect your placement in google and can damage your high quality score if advertising and marketing with Adwords. Well I’m adding this RSS to my email and can look out for a lot more of your respective exciting content. Make sure you update this again very soon.

I need to to thank you for this fantastic read!! I certainly enjoyed every bit of it. I have you saved as a favorite to look at new things you post…

Hi! I realize this is kind of off-topic but I had to ask. Does operating a well-established blog like yours require a massive amount work? I am completely new to running a blog however I do write in my diary every day. I’d like to start a blog so I can easily share my experience and thoughts online. Please let me know if you have any recommendations or tips for new aspiring bloggers. Appreciate it!

I’ve read several excellent stuff here. Definitely value bookmarking for revisiting. I surprise how so much effort you put to create one of these fantastic informative website.

Marvelous, what a blog it is! This weblog presents useful data to us, keep it up.

Hi mates, pleasant paragraph and nice urging commented here, I am genuinely enjoying by these.

Excellent pieces. Keep writing such kind of information on your blog. Im really impressed by your blog.

Hey there, You have done an excellent job. I’ll certainly digg it and personally recommend to my friends. I am sure they will be benefited from this website.

Hi there to every body, it’s my first go to see of this blog; this weblog carries awesome and genuinely good information in favor of visitors.

Having read this I thought it was rather informative. I appreciate you spending some time and energy to put this article together. I once again find myself personally spending a lot of time both reading and posting comments. But so what, it was still worthwhile!

It’s an remarkable article for all the web people; they will obtain benefit from it I am sure.

Awesome! Its really remarkable post, I have got much clear idea concerning from this article.

Way cool! Some extremely valid points! I appreciate you penning this post plus the rest of the website is also really good.

It’s hard to find well-informed people in this particular topic, however, you seem like you know what you’re talking about! Thanks

I’m not sure the place you are getting your information, but good topic. I must spend a while learning much more or working out more. Thanks for wonderful information I used to be in search of this information for my mission.

What’s up to all, it’s genuinely a pleasant for me to visit this site, it contains priceless Information.

Good post. I learn something new and challenging on sites I stumbleupon everyday. It will always be exciting to read articles from other authors and use something from their web sites.

You’re so awesome! I don’t think I’ve truly read through a single thing like that before. So good to find somebody with unique thoughts on this topic. Really.. thanks for starting this up. This site is something that is required on the web, someone with some originality!

Nice post. I learn something new and challenging on blogs I stumbleupon everyday. It will always be helpful to read through articles from other writers and practice something from their web sites.

Hi to all, how is everything, I think every one is getting more from this website, and your views are good for new people.

Hi! This is my first visit to your blog! We are a team of volunteers and starting a new initiative in a community in the same niche. Your blog provided us beneficial information to work on. You have done a wonderful job!

My partner and I stumbled over here from a different web page and thought I should check things out. I like what I see so now i am following you. Look forward to finding out about your web page again.

Good blog you have got here.. It’s difficult to find excellent writing like yours these days. I truly appreciate individuals like you! Take care!!

Hello there! I just wish to offer you a big thumbs up for the excellent information you’ve got right here on this post. I’ll be coming back to your web site for more soon.

Nice post. I was checking constantly this blog and I am impressed! Extremely useful info specifically the last part 🙂 I care for such info much. I was seeking this particular info for a long time. Thank you and good luck.

Hello! I’ve been following your website for a long time now and finally got the courage to go ahead and give you a shout out from Austin Texas! Just wanted to say keep up the great work!

Valuable info. Lucky me I discovered your site by chance, and I’m stunned why this accident didn’t came about earlier! I bookmarked it.

Hi there everyone, it’s my first visit at this site, and post is really fruitful in favor of me, keep up posting these articles.

Pretty portion of content. I just stumbled upon your weblog and in accession capital to claim that I get actually enjoyed account your weblog posts. Anyway I’ll be subscribing for your feeds and even I achievement you get right of entry to constantly quickly.

Gango is truly the best of all

I declare this

Now Now Now

Rhank you

I need to to thank you for this wonderful read!!

I definitely loved every little bit of it. I’ve got you book-marked to check out new

stuff you post…

I’ll right away take hold of your rss feed as I can not find your e-mail subscription link or newsletter service. Do you have any? Please permit me recognize so that I may just subscribe. Thanks.

Hi there! Would you mind if I share your blog with my zynga group? There’s a lot of folks that I think would really appreciate your content. Please let me know. Thanks

I was excited to discover this web site. I need to to thank you for ones time for this particularly wonderful read!! I definitely savored every little bit of it and I have you book-marked to see new things on your website.

Pretty part of content. I just stumbled upon your website and in accession capital to assert that I acquire actually enjoyed account your blog posts. Any way I’ll be subscribing to your feeds and even I success you access constantly rapidly.

This is my first time pay a quick visit at here and i am actually happy to read all at one place.

Hi! I’ve been reading your blog for a long time now and finally got the courage to go ahead and give you a shout out from Huffman Texas! Just wanted to say keep up the good job!

Link exchange is nothing else except it is only placing the other person’s web site link on your page at appropriate place and other person will also do similar in favor of you.

An outstanding share! I have just forwarded this onto a friend who had been doing a little homework on this. And he in fact bought me lunch because I discovered it for him… lol. So let me reword this…. Thanks for the meal!! But yeah, thanks for spending some time to discuss this issue here on your web site.

Can you tell us more about this? I’d care to find out some additional information.

Undeniably believe that which you stated. Your favorite reason seemed to be on the web the easiest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they plainly don’t know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side effect , people can take a signal. Will likely be back to get more. Thanks

My partner and I absolutely love your blog and find a lot of your post’s to be precisely what I’m looking for. Do you offer guest writers to write content to suit your needs? I wouldn’t mind publishing a post or elaborating on a number of the subjects you write about here. Again, awesome web log!

Link exchange is nothing else except it is simply placing the other person’s weblog link on your page at appropriate place and other person will also do same in favor of you.

Hi! I could have sworn I’ve visited this blog before but after browsing through some of the articles I realized it’s new to me. Regardless, I’m certainly delighted I found it and I’ll be bookmarking it and checking back frequently!

you are actually a good webmaster. The site loading pace is amazing. It sort of feels that you are doing any unique trick. Furthermore, The contents are masterwork. you have performed a excellent process in this subject!

You actually make it seem really easy along with your presentation but I find this matter to be actually something that I believe I would by no means understand. It seems too complex and very extensive for me. I’m looking forward in your subsequent post, I will attempt to get the hang of it!