Blog

How is plywood manufactured?

All plywood is manufactured pretty much the same. There are a variety of types and varying numbers of laminations, but the process is the same. They peel off a layer of thick veneer from a log and cut it, alternating the layers and grain patterns. Then the final layer is often a better grade of hardwood veneer. One side is usually the finish side the other not so much. Sometimes they include a layer of MDF just before the final top and bottom veneer. This helps provide a very flat surface for the veneer, avoiding any irregularities due to grain. Most suppliers provide different grades. A “Shop grade” or “Premium”. The latter will often contain the MDF layers. A general rule is the more laminated layers the better the plywood.

Product Process

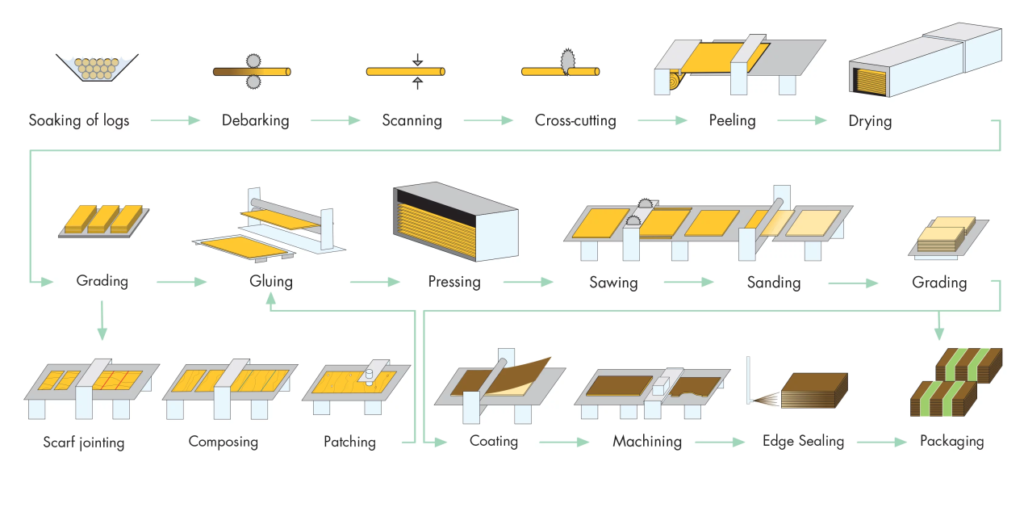

A tree is cut down. When the wood is still green or wet, the log is debarked. The log is then slit or peeled into ribbons the length of the log. The veneers as they are called are graded for knots and grain structure etcetera.

The veneers are then moved to a press and glue up the machine. There, depending on the class of sheet required the face veneer is paid down. Then the inner veneers are laid down in an alternating pattern, so that the grain crosses. This is what gives the final sheet its structural strength. As each veneer is laid, it is sprayed with a glue or bonding agent. Once the correct number of veneers are layered, a top face veneer is added. Then the entire stack is placed inside a heated press where extreme pressure and heat are used to thickness the sheet to final size and to cure the glue. After a period of time, the sheet is removed from the press and inspected. If it passes initial inspection it is sent to the finishing area where it is cut to size. typically 4 ft x 8 ft in the US. It is then graded again. If it is perfect it is sent to final sanding. If it has cracks in the surface veneer or knots that need to be filled, it is sent for rework for voids to be filled and final sanding.

the sheets are then finally graded for each face. Labeled as such bundled according to grade and shipped to the customer.

this answer is a quick outline of generic plywood manufacturing. There are many details, not covered as this is not a place to write a book. This msg like species of tree, final grading of plywood, types of plywood for things like siding vs furniture. Pressure-treating for ground contact, VOC, and formaldehyde constraints on adhesives add many charters to a book on how to make “Plywood”